Blog

Premium Inspection Cameras for Manufacturing Precision and Efficiency Redefined

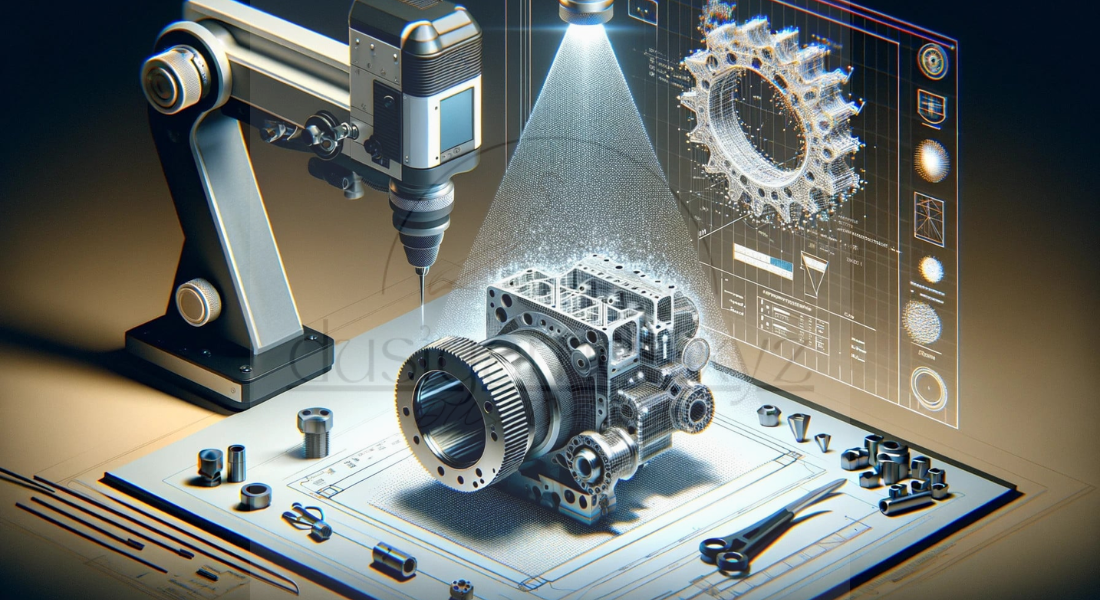

In the ever-evolving manufacturing industry, precision and efficiency are paramount. Premium inspection cameras for manufacturing have become indispensable tools, empowering companies to achieve unparalleled quality control, minimize downtime, and enhance productivity. These advanced devices offer cutting-edge technology tailored to the demanding needs of modern industries.

The Growing Role of Inspection Cameras in Manufacturing

Inspection cameras have transformed how manufacturers ensure product quality and maintain equipment. With the ability to access hard-to-reach areas and capture high-resolution visuals, these devices help detect defects, monitor processes, and maintain operational efficiency. As industries move toward automation and precision, premium cameras are becoming a must-have for businesses looking to stay competitive.

What Sets Premium Inspection Cameras Apart

The best inspection cameras stand out due to their superior image clarity, robust construction, and advanced features. These cameras often include real-time recording, wireless connectivity, and compatibility with analysis software, making them powerful tools for quality control and maintenance tasks.

Precision Imaging for Flawless Quality Control

Accurate imaging is at the heart of effective inspections. Premium inspection cameras for manufacturing deliver high-resolution visuals, enabling technicians to identify even the smallest defects or irregularities. With their exceptional clarity, these cameras ensure products meet strict quality standards, minimizing waste and rework.

Versatility Across Multiple Industries

The versatility of inspection cameras makes them valuable across various sectors, including automotive, aerospace, electronics, and pharmaceuticals. Whether inspecting welds, circuit boards, or packaging lines, these devices adapt to the unique challenges of each industry, ensuring reliable results in diverse environments.

Reduce Downtime with Proactive Maintenance

Unexpected equipment failures can be costly. Inspection cameras allow manufacturers to detect wear and tear before it leads to breakdowns. By identifying potential issues early, companies can schedule maintenance proactively, reducing downtime and maintaining smooth production workflows.

Real-Time Feedback for Immediate Action

In high-speed manufacturing, delays in addressing issues can escalate costs. Premium inspection cameras provide real-time feedback, allowing technicians to address problems immediately. This rapid response capability ensures that defects are resolved quickly, preventing production bottlenecks.

Enhance Safety with Non-Invasive Inspections

Traditional inspection methods often require disassembling machinery, which can be time-consuming and risky. Premium inspection cameras for manufacturing eliminate this need, enabling non-invasive inspections that protect both technicians and equipment. These tools improve workplace safety while maintaining operational efficiency.

Advanced Lighting Solutions for Superior Visibility

Manufacturing environments often involve low-light or confined spaces, where visibility is a challenge. High-quality cameras feature built-in LED lighting with adjustable brightness settings, ensuring clear visuals in any condition. This enhanced visibility improves inspection accuracy and reduces errors.

Streamline Data Management with Intelligent Software

Premium inspection cameras often integrate with data analysis software, making it easy to store, review, and analyze footage. This functionality allows manufacturers to track trends, identify recurring issues, and optimize processes, leading to improved efficiency and reduced costs.

Rugged Designs for Challenging Conditions

Manufacturing environments can be harsh, with exposure to heat, dust, and chemicals. Premium inspection cameras for manufacturing are built to withstand these conditions, featuring durable materials and protective coatings. Their robust construction ensures reliable performance, even in the toughest scenarios.

Flexible Configurations for Specialized Tasks

Not all inspections are the same. Premium cameras come in various configurations, including borescopes, fiberscopes, and robotic models. These designs cater to specific tasks, such as inspecting narrow pipes, intricate machinery, or large industrial equipment.

Automation and AI Integration for Smarter Inspections

As manufacturing embraces Industry 4.0, inspection cameras are evolving with AI and automation capabilities. These systems can automatically detect defects, classify anomalies, and provide actionable insights, reducing the need for manual intervention and enhancing productivity.

Reduce Waste with Precise Quality Checks

Defective products can lead to significant waste, both in materials and labor. Inspection cameras minimize waste by ensuring defects are identified and corrected early in the process. This precision not only saves resources but also aligns with sustainable manufacturing practices.

Increase Productivity with Faster Inspections

Time is critical in manufacturing, and inspection cameras speed up the quality control process. Their ability to capture high-resolution images quickly and efficiently allows teams to complete inspections faster, freeing up resources for other tasks.

Compatibility with Robotic Systems

Robotics and automation are becoming integral to manufacturing. Inspection cameras designed to integrate with robotic systems enable advanced applications such as automated quality checks, reducing human error and increasing throughput.

Tailored Solutions for Unique Manufacturing Needs

Each industry has its own challenges, and premium cameras offer tailored solutions to meet these demands. From specialized lenses to customized software, manufacturers can select features that align with their specific inspection requirements, ensuring maximum utility and value.

Eco-Friendly Options for Sustainable Operations

Modern manufacturing prioritizes sustainability, and inspection cameras contribute by reducing waste and improving efficiency. Additionally, many premium models are designed with eco-friendly materials and energy-efficient components, supporting green initiatives.

Improve Resale Value of Equipment

Well-maintained machinery holds its value better, and regular inspections play a crucial role. Premium inspection cameras for manufacturing help keep equipment in top condition by identifying and addressing issues early, enhancing resale value when it’s time to upgrade.

A Worthwhile Investment for Long-Term Gains

While premium inspection cameras may require an upfront investment, their long-term benefits far outweigh the cost. By improving quality control, reducing downtime, and streamlining processes, these tools deliver substantial returns over time.

Popular Features to Look For in Premium Cameras

When choosing an inspection camera, consider features such as:

- High-resolution imaging for detailed visuals.

- Durable construction to withstand tough environments.

- Wireless connectivity for remote monitoring.

- Data storage and analysis for process optimization.

- Customizable configurations for specific tasks.

Gain a Competitive Edge with Premium Technology

In a competitive market, investing in cutting-edge tools like inspection cameras demonstrates a commitment to quality and innovation. This investment not only improves product outcomes but also enhances brand reputation, attracting more clients and opportunities.

Future Trends in Inspection Cameras

The future of manufacturing inspections lies in integrating advanced technologies such as AI, machine learning, and augmented reality. These innovations promise greater accuracy, faster inspections, and seamless integration with other manufacturing systems, solidifying the role of premium cameras in smart factories.

Why Choose Premium Inspection Cameras for Manufacturing

For manufacturers aiming to achieve excellence, premium inspection cameras for manufacturing are a game-changer. These tools enhance efficiency, ensure consistent quality, and provide valuable insights for process improvement.

Upgrade your manufacturing operations today by investing in premium inspection cameras. Experience the difference they make in ensuring precision, reducing costs, and setting new standards for quality in your industry. With the right tools, the future of manufacturing is yours to shape.