Blog

High End Equipment for Machine Inspection Redefines Quality Assurance

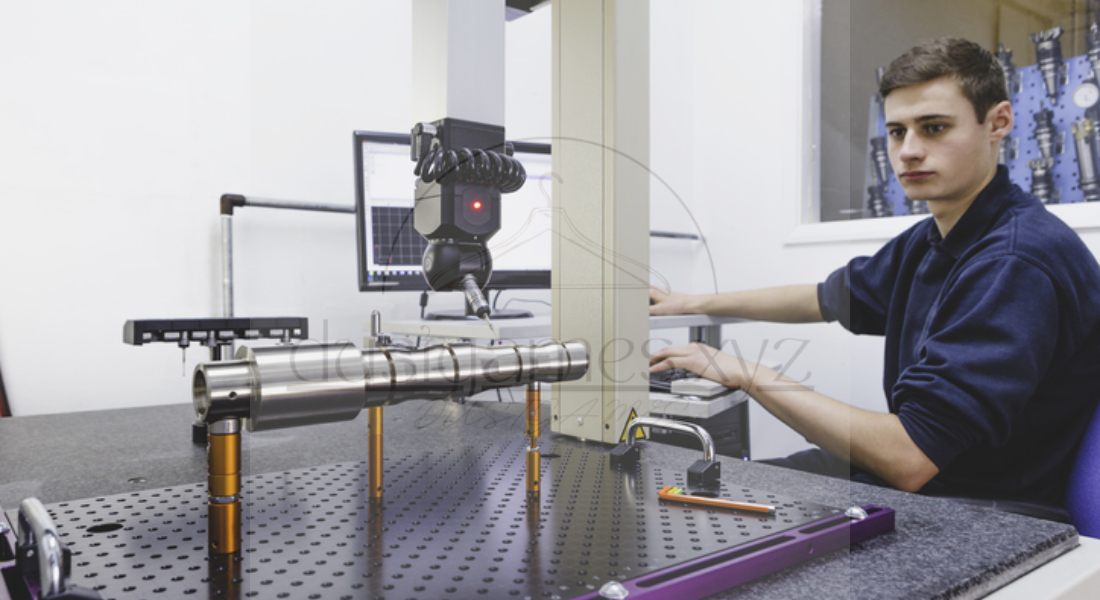

Modern industries demand precision and efficiency to stay competitive. High end equipment for machine inspection plays a vital role in ensuring that machinery operates at peak performance while meeting quality and safety standards. This article explores how these advanced tools transform inspection processes and deliver unparalleled benefits across industries.

Streamline Quality Control with Precision Technology

High end equipment for machine inspection revolutionizes quality control by providing unmatched accuracy. These tools use cutting-edge technology such as 3D scanning, ultrasonic testing, and infrared imaging to detect issues with unparalleled precision.

By analyzing machine components in detail, these systems identify even the smallest flaws. This accuracy not only ensures compliance with quality standards but also minimizes the risk of equipment failure, improving overall operational reliability.

Proactive Maintenance with Real-Time Monitoring

Monitoring machinery in real time helps industries avoid costly downtime. High end equipment for machine inspection offers real-time data collection and analysis, allowing operators to monitor performance continuously.

These systems provide insights into vibration, temperature, and wear patterns, enabling businesses to address potential problems before they escalate. Proactive maintenance reduces repair costs and keeps production schedules on track.

Non-Destructive Testing Preserves Equipment Integrity

Non-destructive testing (NDT) is a core feature of high end equipment for machine inspection. This method evaluates machinery without causing damage, making it ideal for assessing critical components.

Technologies like magnetic particle inspection, eddy current testing, and radiographic imaging ensure thorough evaluations while preserving the integrity of parts. NDT reduces downtime and eliminates unnecessary replacements, enhancing productivity and cost-efficiency.

Customizable Solutions for Diverse Applications

Different industries have unique inspection needs, and high end equipment for machine inspection provides tailored solutions. From heavy-duty machinery in manufacturing to delicate components in aerospace, these tools adapt to a variety of applications.

Customizable features, such as adjustable sensors and modular designs, ensure that inspection systems meet specific requirements. This flexibility allows businesses to achieve precision and efficiency across various operational scenarios.

Advanced Imaging for Detailed Analysis

Imaging technology is at the forefront of high end equipment for machine inspection. High-resolution cameras, thermal imaging, and 3D mapping provide detailed visuals of machinery, helping operators identify issues quickly.

Thermal imaging detects overheating, while 3D scanning creates accurate models for precise measurements. These advanced imaging capabilities ensure comprehensive inspections, leaving no detail overlooked.

Portable Devices Enhance Inspection Versatility

Portable high end equipment for machine inspection offers flexibility for on-site evaluations. Compact and lightweight, these devices are easy to transport and operate in challenging environments.

Portable tools are invaluable for industries like construction, oil and gas, and transportation, where machinery often operates in remote or confined spaces. These devices provide the same level of accuracy as larger systems, ensuring consistent results.

AI-Powered Insights for Smarter Operations

Artificial intelligence enhances the capabilities of high end equipment for machine inspection. AI algorithms analyze data, identify patterns, and predict potential failures with remarkable accuracy.

These insights enable smarter decision-making, allowing operators to optimize maintenance schedules and reduce downtime. AI-driven systems also improve the speed and accuracy of inspections, streamlining workflows and boosting productivity.

Seamless Integration with IoT Networks

IoT integration transforms high end equipment for machine inspection into a connected system. Sensors, machines, and analytics platforms communicate in real time, providing a holistic view of operations.

IoT-enabled inspection tools offer centralized data management, making it easy to track machine performance, generate reports, and identify trends. This connectivity supports predictive maintenance and enhances overall efficiency.

Reduce Costs with Predictive Maintenance

Predictive maintenance relies on data collected by high end equipment for machine inspection to prevent costly repairs. These tools identify potential issues before they lead to equipment failure, reducing repair expenses and downtime.

By replacing components only when necessary, businesses save on material costs while maintaining optimal performance. Predictive maintenance also extends the lifespan of machinery, maximizing return on investment.

Remote Inspections for Hard-to-Reach Areas

High end equipment for machine inspection includes remote solutions like drones and robotic systems. These tools access confined or hazardous spaces, capturing detailed data without putting personnel at risk.

Remote inspections are particularly useful in industries such as oil and gas, where pipelines and structures are difficult to reach. These systems enhance safety while maintaining the precision and thoroughness of traditional methods.

Enhance Safety with Advanced Inspection Tools

Safety is a top priority in industrial operations, and high end equipment for machine inspection helps maintain it. By detecting potential hazards, such as structural weaknesses or overheating components, these tools prevent accidents and equipment failure.

Inspection tools equipped with real-time alerts enable operators to address issues immediately. This proactive approach ensures a safer working environment for personnel and protects valuable assets.

Durable Designs for Challenging Environments

High end equipment for machine inspection is built to withstand tough conditions. Rugged designs and weatherproofing ensure these tools perform reliably in extreme environments.

Industries like mining, manufacturing, and marine operations benefit from durable inspection systems that endure heavy usage, moisture, and extreme temperatures. Reliable equipment ensures uninterrupted inspections, regardless of external conditions.

Digital Reporting Simplifies Compliance

Detailed reporting is essential for maintaining compliance with industry regulations. High end equipment for machine inspection generates digital records, simplifying documentation and improving traceability.

These reports provide actionable insights and ensure that inspections meet regulatory standards. Digital reporting also streamlines audits, saving time and reducing administrative workloads.

Eco-Friendly Solutions for Sustainable Operations

Sustainability is a growing focus for many industries, and high end equipment for machine inspection supports eco-friendly practices. By reducing waste and optimizing energy use, these tools align with environmental goals.

Predictive maintenance minimizes unnecessary part replacements, while non-destructive testing preserves valuable materials. Businesses achieve operational efficiency while reducing their environmental impact.

Future-Ready Technology for Evolving Needs

Investing in high end equipment for machine inspection ensures businesses stay ahead in a competitive landscape. As technology evolves, these systems adapt with advanced features and regular updates.

Future-ready inspection tools enable industries to embrace innovation and respond to changing demands. This adaptability positions businesses as leaders in their field, ensuring long-term success.

Conclusion: Transform Your Inspection Processes Today

High end equipment for machine inspection redefines quality assurance across industries. From advanced imaging to AI-driven insights, these tools deliver precision, efficiency, and reliability.

Investing in modern inspection systems enhances productivity, reduces costs, and supports sustainable practices. Whether monitoring machinery in real time or conducting remote evaluations, this technology empowers businesses to achieve excellence.

Take your inspection processes to the next level with high end equipment designed for success. With the right tools, your operations achieve greater accuracy, safety, and performance in every project.